In the current high-voltage and extra-high-voltage solar power market, the share of distributed power conditioners (PCS) is rapidly expanding.

As the number of DC input circuits increases, maintenance costs are also rising, along with higher failure rates, making these major challenges.

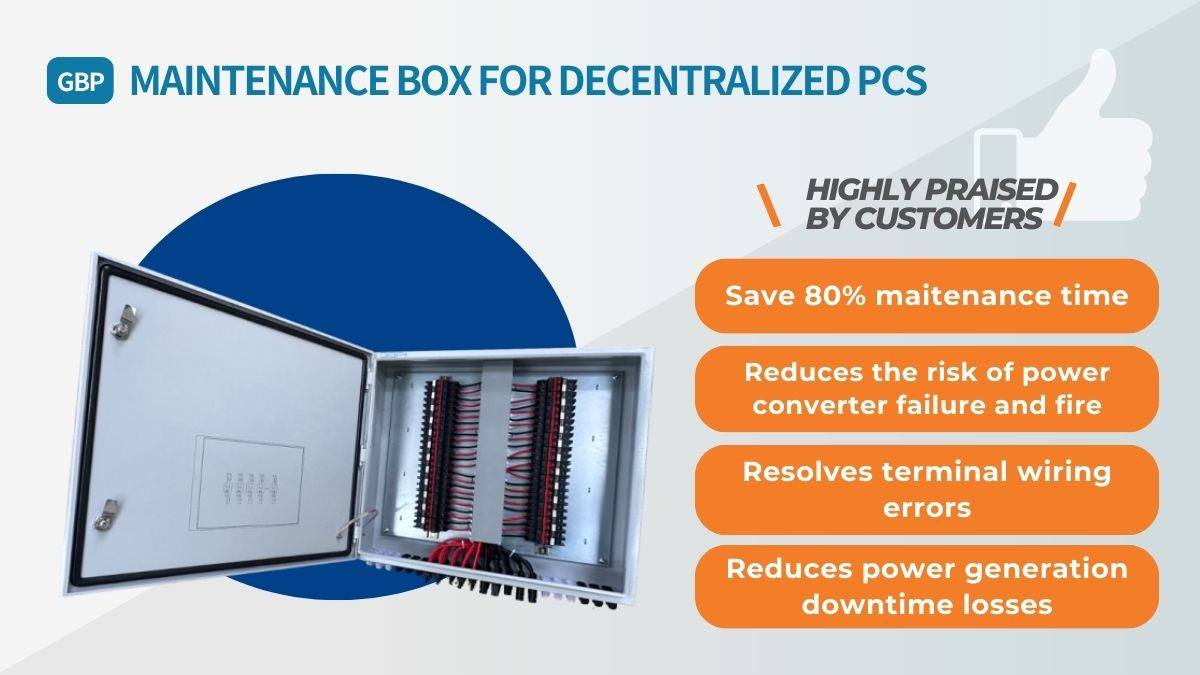

By introducing GBP's maintenance boxes for distributed PCS systems, you can reduce maintenance time by 80%, eliminate terminal wiring errors, and achieve long-term cost savings on maintenance.

Challenges During Maintenance

High Cost of MC4 Connector Operations

For a 2MW site with 20 units of 100kW distributed PCS over 20 years, inspection costs can reach approximately 4 million yen.

- Plugging and unplugging operations: 20 units × 24 circuits × 20 years = 8,000 operations

- Inspection time: 8,000 operations × 5 minutes/operation = 667 hours

- Labor costs: 667 hours × 3,000 yen/hour = 2 million yen

- Power generation loss due to downtime: 667 hours × 100kW × 30 yen = approximately 2 million yen

Inverter Quality Assurance and Fire Risk Factors

・Aging of Plastic Components: Over time, plastic connectors can degrade, causing breakages that can lead to electrical faults.

・Variability in Workmanship: Differences in seasonal conditions and the skill levels of workers can result in poor-quality connections, increasing the risk of faults and failures.

・High Circuit Density: A large number of circuits increases the likelihood of mismatched connections, which can cause inverter failures.

・Non-Coverage by Warranty: Defects due to terminal issues are typically not covered by standard inverter warranties, leaving customers exposed to potential risks.

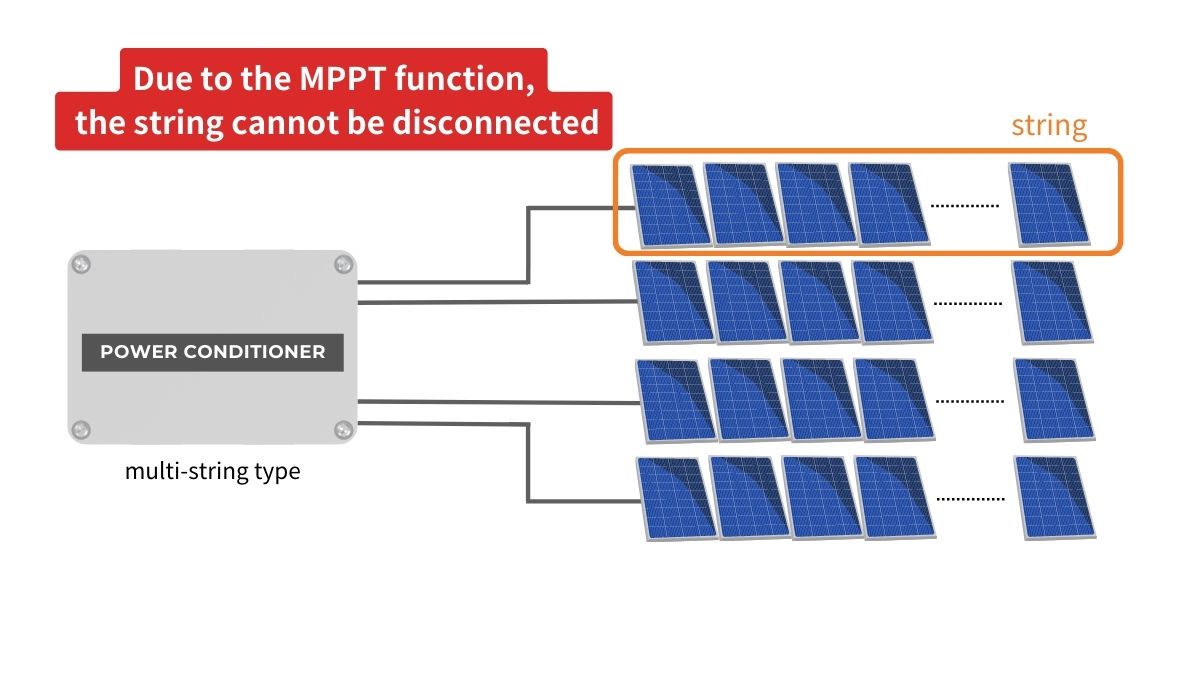

Inability to Disconnect Individual Strings

With 2 to 4 strings per MPPT circuit, individual circuit disconnections are not possible, requiring the PCS to stop power generation during inspections.

Industry-first

▶︎

| GBP’s Solution |

|---|

|

Our maintenance boxes make inspections easy, reducing both labor costs and power generation downtime losses.

The switches in the maintenance box are user-friendly, allowing for quick and efficient inspections. By centralizing operations, you can significantly reduce construction periods, installation costs, and maintenance expenses.

|

|

Reduce the risk of failures and fire hazards caused by defective terminals.

Maintenance box operations help mitigate the degradation of plastic connectors over time, improving overall safety. Completely eliminate terminal wiring errors.

|

|

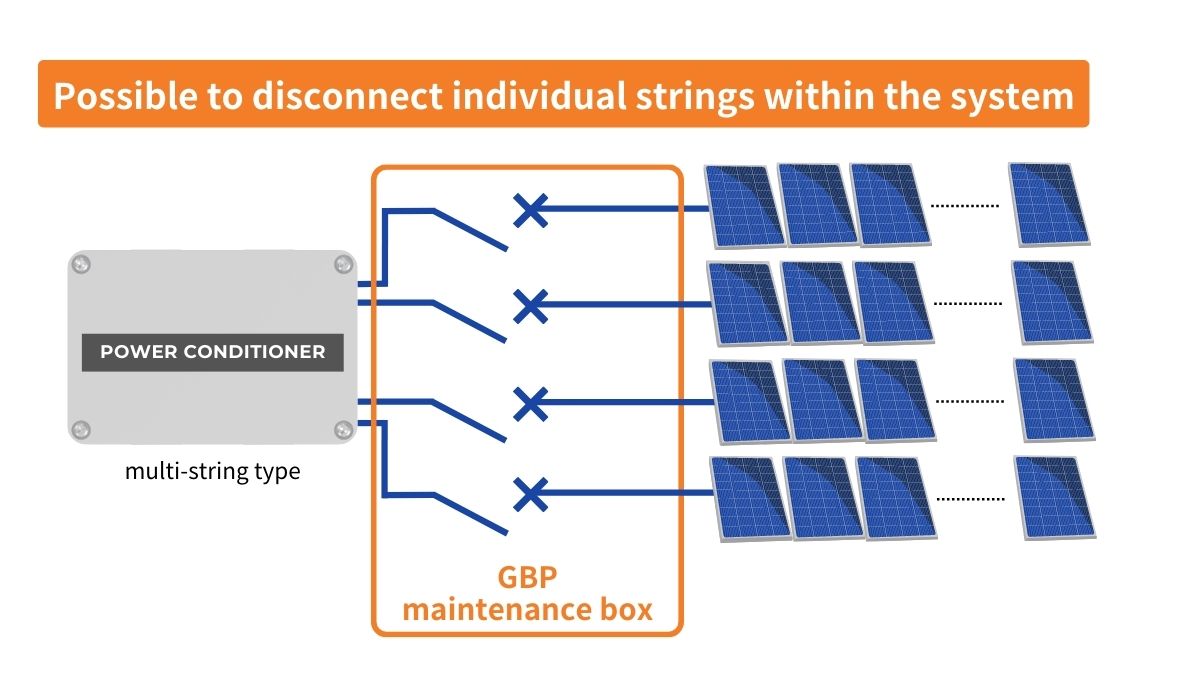

String-Level Disconnection

-The maintenance boxes allow for string-level disconnection, eliminating the need to stop PCS power generation during inspections.

|

Highly Customizable

▶︎

| Feature | Specifics | Advantage |

|---|---|---|

| Input Voltage(DC) | 1500V, 1000V, 750V etc. | Customizable based on customer requirements |

| Input Circuits | 2, 4, 6, 8, 10, 12, 16, 18, 20, 24, 26, 32 Circuit etc. | Customizable based on customer requirements |

| Connection Methods | MC4 connectors, OT terminals, copper bars | Customizable based on customer requirements |

| Enclosure Materials | Stainless steel, steel plates, plastic | Designed to handle complex environments |

| Installation Environments: | Suitable for land, water, offshore, | Possible to install in harsh environments with high temperatures, humidity, and heavy salt damage |

| Installation Methods | Roof-mounted, horizontal placement, wall-mounted | Adaptable for self-consumption sites, power plants, and more |

| Optional Features | Blocking diodes for reverse current prevention, | Lightning protection SPD, remote monitoring and control, overcurrent protection |

Performance and Specifications

・Protection Rating:IP65

・Insulation Resistance≥10MΩ

・Insulation Withstand Voltage:3820VDC

Product Specifics

・Compact Switchgear and Simplified Wiring Terminals

・Consultations Available for Single Units

・Compatible with Existing Legacy Junction Boxes

・Compliant with IEC, JIS, 3C, and TUV Standards

・In-Stock Products Available Domestically for Fast Delivery

・Supported Distributed Power Conditioners: 20kW, 33.3kW, 49.5kW, 62kW, 100kW, 111kW, 125kW, 140kW, 150kW

・Supported Inverter Manufacturers: Huawei, Sungrow, SMA, Delta, ABB, Tabuchi Electric, Fuji Electric, and more

CATALOG

CATALOG